First published in The Straits Times on 19 March 2020.

Before striking out on his own, Mr Koh San Joo worked in a logistics firm where day-to-day operations such as inventory management and order processing were driven by manual labour.

These processes — often tedious and time-consuming — spurred Mr Koh to digitalise iHub Solutions, the supply chain logistics business he started in 2000.

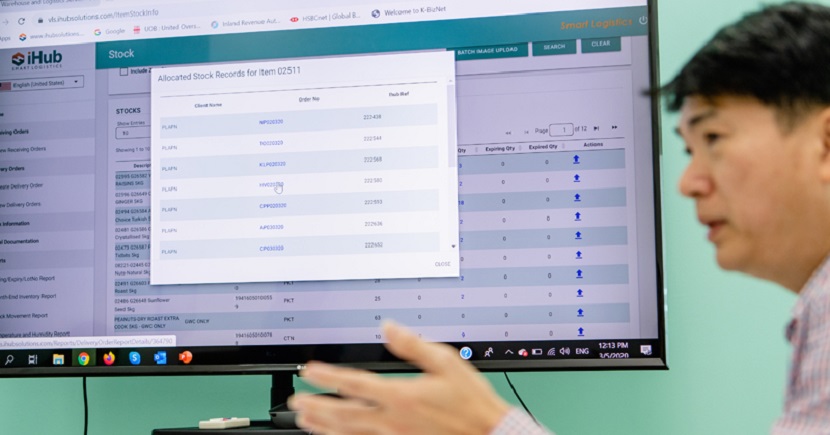

In the first few years of business, iHub rolled out a proprietary Virtual Logistics System (VLS) that enabled employees and customers to track and trace the movement of goods and services online 24/7.

With the web-based integrated platform, users could manage and monitor inventory and orders, upload images and digitalise invoices, set replenishment and expiry alerts, and view signed proofs of deliveries in real time.

“I wanted to offer complex logistics services to differentiate myself and you need technology to do that,” said Mr Koh.

The 58-year-old managing director explained that complex logistics are supply chain processes requiring deep domain expertise, from synchronising information flow and financials to digitising a logistics network.

Today, the firm has about 200 clients, spanning multinational corporations and small and medium enterprises, across Singapore, Malaysia, Hong Kong, Thailand and the Philippines.

Going digital has been a significant part of its success. It invests nearly half a million dollars every year to build its in-house research team’s capabilities and develop software and hardware.

Mr Koh shared that the investment has helped iHub to improve its processes and remain profitable. The firm posted a compounded annual growth rate of 15 per cent between 2013 and 2019.

Last October, it received the Singapore Quality Class with Innovation certification from Enterprise Singapore. The business excellence certification recognises companies that excel through digital transformation and a culture of innovation.

A smart warehouse

iHub’s digitalisation efforts are apparent. At its Jurong warehouse, employees process inbound and outbound goods with smart tablets, which are integrated with the VLS platform to sync up storage and downstream tasks, such as cargo load balancing and delivery route planning.

“We store more than 100,000 products for more than 100 clients with local operations in our Jurong warehouse, and our stock accuracy rate is more than 99.9 per cent,” said Mr Koh.

Information such as when the goods arrived at the warehouse, how many days they have been stored, and the expiry dates of perishables are uploaded to the VLS.

Details are then updated in real-time for clients to keep track of their inventory and glean useful insights. For instance, a company can clear excess stock in iHub’s warehouse by reducing orders for the product or selling it at lower prices.

iHub also built application programming interfaces so clients could integrate their enterprise resource planning systems and e-commerce stores with digital marketplaces such as Qoo10, Lazada and Shopify. With this service, the firm’s clients can oversee and manage their orders across different sales channels seamlessly.

Tracking transport

As business grew, iHub sought to optimise its delivery system.

In 2013, it customised and implemented a Cloud Transport System (CTS) with the help of Enterprise Singapore. Other digitisation initiatives also received the support of the enterprise development agency.

The CTS platform manages delivery routes and assignments for drivers, reducing man hours spent on these tasks. In addition, it tracks drivers’ locations so that the firm can reassign deliveries to quicken routes when necessary and inform customers of updated delivery times.

The platform also helps iHub to keep an eye on driving-related performance metrics through navigation systems and sensors attached to delivery vehicles. With this data, the firm has been able to weed out unsafe and fuel- wasting driving habits.

Last year, iHub achieved its goal of cutting road accidents caused by its drivers to zero. It also received the GFA Label – Leaf 2 from non-profit organisation Green Freight Asia. The award recognises businesses that have passed the criteria for regular vehicle maintenance, use of fuel-efficient technologies and providing eco-driving training to drivers.

Other CTS platform improvements include the tracking of cash cards to match parking expenses and electronic road pricing against mapped locations and delivery addresses. These automated processes enable paperless cash reimbursements and encourage transparency within the company.

Logistics executive Aminah Abdullah noted that some drivers were resistant when the firm first introduced the CTS.

“We prepared them beforehand and explained how these measures would help us to attract more customers. They are now very supportive because they have seen that our business has grown and they are getting more work,” she said.

More digitisation projects are in the pipeline for the company, with plans to introduce automated guided vehicles, butler robots and artificial intelligence (AI) to build an AI-powered supply chain.

“We have to keep improving ourselves,” said Mr Koh. “That’s the only way we will stay relevant to our customers, provide higher-skilled jobs for our staff and be better than our competitors.”

iHub's 3 tips for growth

iHub Solutions now operates in Singapore and four overseas markets, but plans to expand to other countries to grow its business and better serve clients eyeing internationalisation. Director Catherine Tan, 50, shares the firm’s growth strategies.

1. Localisation is key

When we expanded into Malaysia, Hong Kong, Thailand and the Philippines, it was at our clients’ invitation. They were impressed with our services in Singapore and wanted us to help them with their logistics in their other markets.

Many companies face challenges in different markets. Logistics is one of them. You need to have a good service that translates well across countries; you might have to make a few tweaks, but it is a good start.

2. Know your audience

Think about how your service bridges a gap in the market. Our digital systems are high-tech and target specific problems. Since they automate repetitive tasks, they are more likely to be successful in countries with high labour costs, such as Taiwan, Japan and South Korea.

Also, the firms that typically need our Virtual Logistics System are those that have complicated logistics and inventory or traceability problems, since the system addresses these issues. You have to know which types of customers to target, and go where you are needed.

3. Invest in training

Training is very important to improve productivity and demonstrate to employees that you are invested in their future at the company. When we opened our overseas offices, we brought some of the employees to Singapore to train them to maintain our standards.

We take part in the SkillsFuture Earn and Learn Programme, Workforce Singapore’s Professional Conversion Programme and other initiatives to find people with fire in their bellies. After you find them, in-depth training is crucial to help them do well.

We teach our employees how to use our systems and machines and enrol them in courses. Our staff are encouraged to think about green, safe and smart principles to develop robust business processes. The Automobile Association of Singapore also conducts lessons on safety and eco-driving for our local drivers, which help us to save fuel and other costs.

Milestones

- 2000: Mr Koh San Joo establishes iHub Solutions to offer supply chain logistics.

- 2003: The firm implements its Virtual Logistics System (VLS), which lets clients track and trace orders around the clock. It opens its first overseas office in Malaysia.

- 2013: The firm rolls out its Cloud Transport System, which automates delivery route assignments, telematics and mobile apps for drivers.

- 2019: The VLS is integrated with application programming interfaces to help businesses synchronise orders across various e-commerce platforms. iHub expands to the Philippines, the latest of its four overseas markets.