First published in The Straits Times on 05 March 2020.

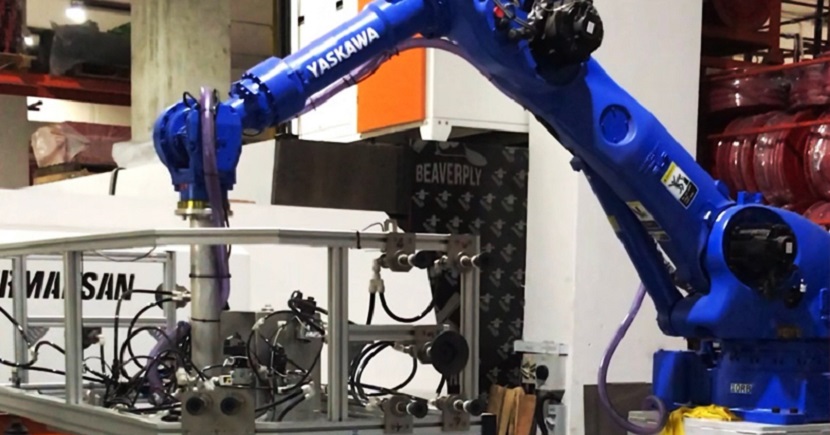

In an industrial building at Woodlands, 14 robotic arms feed sheet metal into machines, shape and weld cut metal and lift heavy cylinders.

These robots may look like automatons straight out of Marvel superhero Tony Stark’s workshop, but they are actually part of firefighting equipment maker Lingjack’s workforce.

Designed to help workers assemble fire extinguishers, these collaborative robots (cobots) have helped to triple the company’s output since they were introduced in 2017.

Such innovation has been critical to Lingjack’s increased productivity and growth, especially amid global uncertainties and change, said chief executive officer Kenneth Lim.

“We want to cater for the new millennium and be two to three steps ahead of the competition,” said the 48-year-old.

“With automation, we have been able to improve our productivity as it helps our company to perform more efficiently with a higher level of consistency and quality.”

Singapore’s only fire extinguisher maker was founded in 1971. Today, its product range includes fire safety equipment like fire hose reels, hydrant valves and sprinklers. It has offices in four countries, with 100 employees and 600 clients worldwide.

To keep pace with fire safety standards and evolving urban landscapes, Lingjack has expanded its product portfolio to include surveillance systems and green firefighting technology.

IoT in fire safety

With support from Enterprise Singapore, Lingjack developed an Internet of Things (IoT) platform last year to enable real-time checks on fire safety equipment in buildings.

The platform, also known as the “Fire Node”, consists of a dashboard and a wireless monitoring system with sensors that can be attached to fire extinguishers.

The sensors track information such as the pressure level in an extinguisher and detect obstacles that may block people’s access to the fire safety apparatus. This data can then be accessed wirelessly via the system’s dashboard, enabling owners or occupants of buildings to identify faults or maintenance issues quickly.

The Fire Node reduces time spent on manual fire safety checks by more than 90 per cent, said Mr Lim.

The technology has begun to gain traction commercially. Last year, Singapore Expo ordered and installed 1,000 nodes to improve inspection of its fire safety devices.

“The system provided us real-time fire extinguisher status updates seamlessly without human intervention,” said Mr James Chua, head of engineering at Singapore Expo’s operator SingEx Venues.

“It totally replaced monthly inspection work and increased our productivity.”

Lingjack’s IoT surveillance system offers more than convenience. It also beefs up fire safety in the digital era, where densely populated cities continue to add to an ever-growing pile of smart devices and network cables.

Electronic devices and cables, when tightly packed and overworked, generate large amounts of heat that can be fire hazards to the community.

The Fire Node assures people that their fire safety devices are fully ready to mitigate such risks, said Mr Lim.

Green firefighters

Beyond fire safety surveillance, Lingjack has also expanded its portfolio to include cleaner firefighting technology.

Last year, the company launched an eco-friendly fire extinguisher that uses a powerful water mist to douse fires.

This is a greener alternative to traditional fire extinguishers, which often contain flame retardants like ammonium sulphate and phosphate that leave behind a residue of corrosive powder when released.

“Conventional extinguishers are safe to use as they have very low levels of lead and mercury. But it will be best to move away from the use of metals because they may cause collateral damage to the surroundings,” said Mr Lim.

The company has received a Green Label certification from Singapore Environment Council for its new extinguisher and counts Singapore Expo, the National University of Singapore and National Gallery Singapore among its users.

Of machines and men

For a long time, Lingjack’s manufacturing operations were labour-intensive; the company depended on 70 production workers to churn out 200,000 fire safety products every year.

To better manage manpower challenges, it automated its processes in 2017 — investing $2 million in robotic arms and laser-cutting and bending machines, with the support of Enterprise Singapore. About 90 per cent of the firm’s work processes are now automated, helping it to achieve a total efficiency gain of 40 per cent.

“Instead of focusing on one process, our staff can take care of multiple processes at once,” said Mr Lim.

“We believe technology can be used to support the efficiency of the fire safety industry in unprecedented ways. It gives you the assurance that your fire safety products will definitely work in emergency situations.”

How Lingjack fuels innovation

1. Be future-proof

In a world of constant change, the spoils go to the nimble. Companies must adapt and regularly review their business models to retain their competitive edge in the market.

Firefighting specialist Lingjack decided to automate its work processes when it realised that it was facing a manpower crunch. By future-proofing its business with the introduction of new innovations such as collaborative robots, the company was able to increase its output and reduce overheads.

2. Be patient

Lingjack has shown that the key to success in innovation is a never-say-die attitude.

The research and development team went through countless prototypes before developing its Internet of Things fire safety node, said product development engineer Chris Soo, 49.

“We scrapped a few prototypes, so we could launch the correct product once and for all,” added chief executive officer Kenneth Lim, 48.

3. Build from within

Hiring engineers skilled in fire safety equipment is next to impossible, said Mr Lim. This spurred Lingjack to develop an in-house R&D team — to foster talent and build capabilities from the ground up.

“If you build your own internal team, you can develop more products and have greater control over them in the future,” he said.

Milestones

- 1972: Mr Lim Suei Kuat sets up Lingjack as a general engineering firm and supplier of metal works.

- 1982: It starts manufacturing its Combat brand of fire extinguishers.

- 1997: It sets up a factory in Woodlands to produce a range of firefighting equipment, such as fire hose reels, hydrant valves and sprinklers.

- 2000: Lingjack starts selling its products in Europe.

- 2006: It expands sales of its products to countries in Asia, including Malaysia, Thailand, the Philippines and India.

- 2017: Lingjack starts automating its work processes.

- 2018: It assembles a research and development team to work on new fire safety products.

- 2019: Lingjack launches the “Fire Node” and an eco-friendly fire extinguisher.